Case Study – Running Cost Comparison Between a NAPR and an AYO WX HFM PAPR

Another important point of a NAPR is that it is reusable, more cost-saving in the long run, and more environmentally friendly. Thus, it is not surprising that NAPR’s market share is on the rise.

However, when it comes to powered air-purifying respirators (PAPRs), especially tight-fitting PAPRs, apart from being elastomeric, they offer better protection by design, as the pressure inside the breathing zone is positive, and they are also more comfortable to breathe.

Research shows that the NAPRs market size was over USD 9.5 billion in 2022, compared with USD 2.4 billion for PAPRs. Assuming an average NAPR is USD 50, and an average PAPR is USD 1000, which is roughly about right, this suggests a ratio of 79:1, meaning for 79 NAPR users, there is only one PAPR user. So there is more room for PAPRs to grow.

In fact, the industry trend is heading for more workers to move up from NAPRs toward PAPRs for better protection. For example, in Australia, the exposure limit for welding fumes is reduced from 5mg/m3 to 1mg/m3, and this almost certainly will demand the use of PAPRs in many welding sites.

However, most PAPRs are much more expensive than NAPRs, and they are also bulky, heavy, and troublesome to use and maintain, and these are the key inhibitors of their adoption. Therefore, it is easy to comprehend that there are more users of NAPRs than PAPRs.

To allow widespread workers to be able to take advantage of the improved protection from PAPR technology, Aimwell invented, designed, and optimized AYO WX HFM Half-Face Mask PAPR System, and we believe it can not only significantly enhance respiratory protection, but can also cost less within 12 months of use compared with typical NAPRs when doing daily dusty work, such as stonework.

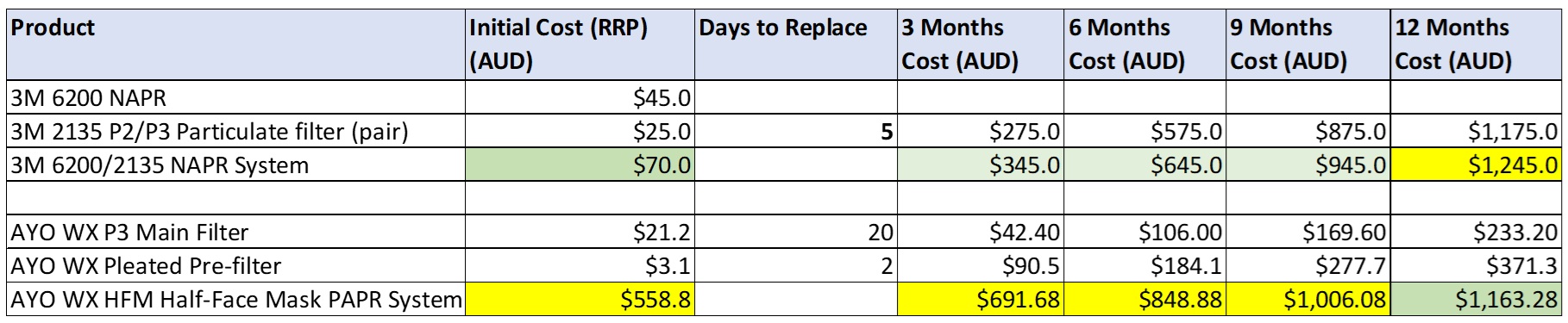

Here is our case study:

Target NAPR: 3M 6200 with 2135 P2/P3 particular filter.

Comparing PAPR: AYO WX HFM Half-Face Mask PAPR System with pleated pre-filter and PAPR P3 HEPA filter.

Target application: Stonework

Estimated Filter replacement:

- 3M 2135 P2/P3 filter: every 5 days

- AYO WX Pleated pre-filter: every 2 days.

- AYO WX Main filter: every 20 days.

Result:

Analysis:

- At initial purchase, the 3M 6200/2135 system costs $70 versus $559 of AYO WX HFM PAPR.

- Due to the design of 2135 particle filter, there is no pre-filter that can be replaced cheaply. As a result, every 5 working days, the whole pair of filters need to be replaced.

- In contrary, AYO WX HFM PAPR has a unique low-cost pleated pre-filter that can capture larger particles with reasonable dust-loading capacity and protect the HEPA filter. As a result, the HEPA filter can last longer while the pleated prefilter can be changed often at a very low cost.

- At 12 months of use, the total cost of use for AYO WX HFM PAPR is $1,163 versus $1,245 for the 3M 6200/2135 system.

Other Considerations

- The above comparison is based on the RRP for one AYO WX HFM Half-face Mask PAPR System. For large organizations with higher order quantity, the unit price will be lower than the RRP, thus the ‘breakeven’ time will be shorter accordingly.

- Being a PAPR, AYO WX HFM PAPR is more comfortable to breathe, especially for long working hours.

- Being a PAPR, AYO WX HFM can tolerate some facial leaks, but being a NAPR, the protection of 3M 6200/2135 is highly sensitive to facial leaks.

- A non-clean-shaven person shall not use a NAPR. However, a person with a short beard may use AYO WX HFM PAPR and still achieve good protection even better than most loose-fitting PAPRs.

- With patented technology, AYO WX HFM PAPR achieves a great wearability similar to common NAPRs. This is dramatically different from most common PAPRs which are bulky and heavy, with poor mobility.

For daily work in highly dusty environments, AYO WX HFM Half-Face Mask PAPR System can not only provide better and more reliable protection than a typical NAPR but also costs less after using for 1 year, in addition to being more comfortable to breathe, making AYO WX HFM PAPR a perfect upgrade from common NAPRs for many industrial respiratory protection applications.