Case Study: Future Form Enhances Worker Safety and Efficiency with AYO WX Loose-Fitting PAPR Systems

Case Study: Future Form Enhances Worker Safety and Efficiency with AYO WX Loose-Fitting PAPR Systems

Eliminating Silica Dust Risks in Construction Without Compromise

Overview

Future Form, a leading formwork and concrete construction company, faced significant challenges protecting its workforce from silica dust—a pervasive hazard in their industry. Traditional solutions like disposable paper masks and non-powered respirators proved inadequate due to fit testing requirements, worker discomfort, and logistical inefficiencies. After adopting the AYO WX FFM-LF Loose-Fitting Full-Face PAPR System, Future Form transformed its safety protocols, achieving compliance, cost savings, and worker satisfaction.

________________________________________

Challenges: Why Traditional Respirators Fell Short

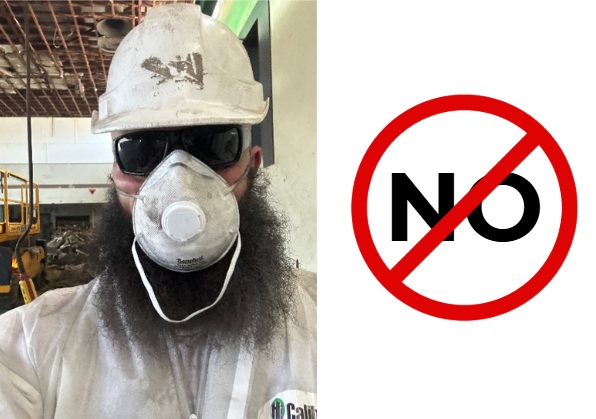

1. Bearded Workers: Many employees wore facial hair, making tight-seal respirators ineffective and forcing costly, uncomfortable shaving mandates.

2. High Contractor Turnover: Frequent onboarding of new contractors required repeated fit testing, delaying projects and increasing expenses.

3. Mobility Constraints: Belt-mounted PAPRs or hose systems hindered workers carrying tools or navigating confined spaces.

4. Cost Barriers: Competitor PAPR systems (e.g., 3M Versaflo) were prohibitively expensive for widespread deployment.

________________________________________

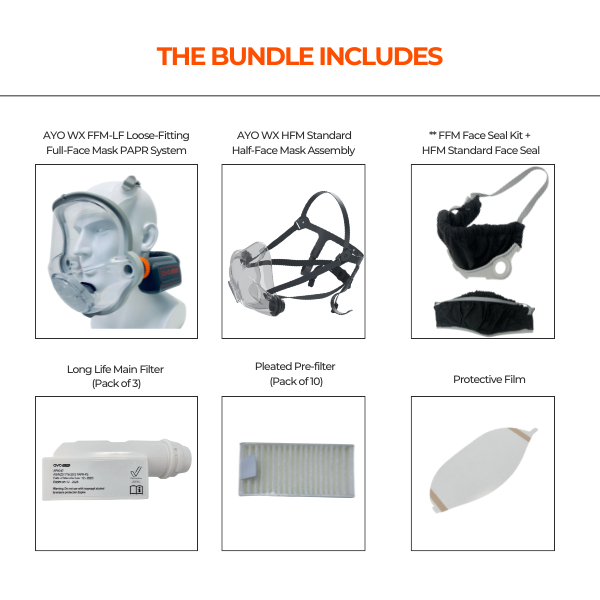

The Solution: AYO WX FFM-LF Loose-Fitting PAPR System

Future Form chose the AYO WX for its unique combination of innovation, practicality, and affordability:

- No Hose, No Belt-Mounted Unit: The lightweight, around-neck design eliminates tripping hazards and frees workers’ waists for tool belts, critical in dynamic job sites.

- Loose-Fitting, No Fit Testing Required: Powered by positive pressure and breath-responsive flow control technology (200+ L/min airflow), it ensures protection without a tight seal—ideal for bearded workers and fast-paced teams.

- Easy to Don/Doff: Perfect for confined spaces or quick adjustments, enhancing productivity.

- Cost-Effective Safety: Priced for scalability, enabling Future Form to equip every worker without sacrificing budget.

________________________________________

Results: Safety Meets Efficiency

• Eliminated Fit Testing: Saved 8+ hours monthly in administrative tasks and testing costs.

• 100% Compliance: Bearded workers and new contractors now have immediate, reliable protection.

• Increased Productivity: Workers reported less fatigue and unrestricted movement, even in tight spaces.

• Worker Satisfaction: Employees praised the comfort and ease of use, with one contractor noting,

“It’s the first mask I can wear all day without itching to take it off.”

________________________________________

Results: Safety Meets Efficiency

• Eliminated Fit Testing: Saved 8+ hours monthly in administrative tasks and testing costs.

• 100% Compliance: Bearded workers and new contractors now have immediate, reliable protection.

• Increased Productivity: Workers reported less fatigue and unrestricted movement, even in tight spaces.

• Worker Satisfaction: Employees praised the comfort and ease of use, with one contractor noting, “It’s the first mask I can wear all day without itching to take it off.”

________________________________________

Why AYO WX FFM-LF is Ideal for Construction Companies

The AYO WX addresses universal pain points in construction:

• High Turnover? Skip fit testing and onboard workers instantly.

• Diverse Workforce? Accommodate beards and facial hair without compromise.

• Mobility-Critical Tasks? The around-neck design ensures unrestricted movement.

• Budget Constraints? Achieve enterprise-grade protection at half the cost of traditional PAPRs.

________________________________________

In Their Words

“The AYO WX changed the game for us. Fit testing is obsolete, and our workers no longer have to choose between safety and comfort.

The cost savings alone justified the switch—but seeing our team embrace the system without complaint? That’s priceless.”

Conclusion: Protect Your Team Like Future Form

For construction companies battling silica dust, the AYO WX FFM-LF delivers unmatched flexibility, compliance, and value.

Say goodbye to fit testing, mobility issues, and costly alternatives.

Ready to Transform Your Safety Program?

Contact us today to learn how the AYO WX can safeguard your team—beards, confined spaces, and tight budgets included.

________________________________________